In today’s competitive manufacturing landscape, companies are under pressure to increase revenue, expand market share, and optimize product development metrics such as cost, quality, and time-to market. However, achieving these objectives is not without its challenges. Market expansion often requires customization and a diverse product portfolio, while product optimization relies on standardized processes that streamline operations.

To balance these conflicting goals, manufacturers must overcome several obstacles, including demand variability, supply chain disruptions, intellectual property risks, and compliance with evolving regulations. The key to navigating these complexities lies in Product Life-Cycle Management (PLM).

What is PLM and Why is it Essential?

PLM is a strategic approach that integrates people, processes, business systems, and information to streamline the entire product life cycle, from initial concept through to production, service, and end-of-life. PLM helps manufacturers optimize product development, reduce costs, and increase time-to-market by offering visibility and control across the entire development process.

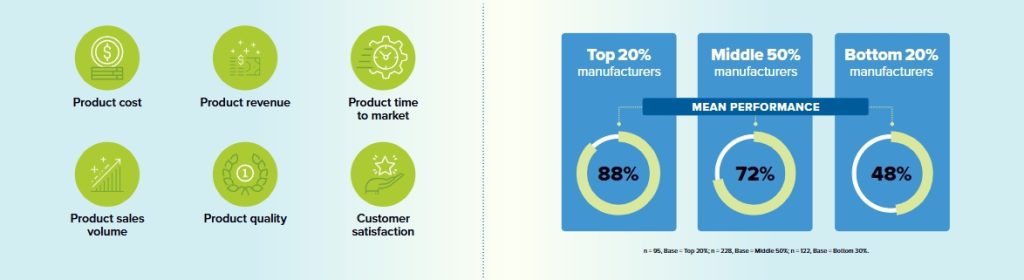

Recent findings from the 2023 IDC Product and Service Innovation Survey, which surveyed 814 manufacturers across North America, Europe, and Asia/Pacific, reveal critical insights into the role of PLM in modern manufacturing. This research highlights that companies using PLM solutions are able to achieve higher success in product development and meet important metrics, including product cost, quality, and revenue.

Key Insights from the IDC Survey

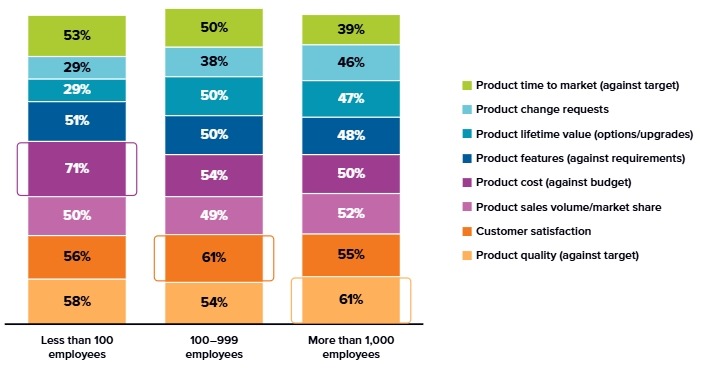

The survey results are segmented into three categories based on product performance: Top 20%, Middle 50%, and Bottom 20% manufacturers. The differences in performance across these groups underline the importance of effective PLM strategies.

- Top 20% of manufacturers consistently meet or exceed product development goals:

- 88% meet product cost and revenue targets.

- 88% meet time-to-market goals.

- 72% meet product sales volume and quality targets.

- 48% meet customer satisfaction objectives.

- Middle 50% and Bottom 20% manufacturers struggle to meet these targets, particularly in areas like product sales volume, quality, and customer satisfaction.

The key takeaway? Manufacturers who leverage PLM to optimize product development processes consistently outperform their competitors, meeting or exceeding critical performance metrics across the board.

The Challenges Manufacturers Face

Manufacturers are grappling with multiple challenges that impact product development, such as:

- Balancing customer demands and market pressures: Manufacturers must deliver products that meet customer expectations for quality, customization, and value.

- Supply chain disruptions: Unpredictable delays and shortages can hinder product development and delay time-to-market.

- Increasing internal costs: As margins tighten, companies must find ways to reduce development costs without compromising product quality.

- Regulatory compliance: Meeting industry regulations and quality standards is becoming increasingly complex as markets evolve.

These challenges often span multiple functions within the organization, and PLM serves as a powerful tool to align teams, processes, and data to address them more effectively.

This article is posted at idc.com

Please fill out the form to access the content